Development and Production

of high quality seamless thermoformed bra cups

Creative solutions tailored to your vision

In the fashion and lingerie industry, bespoke solutions are critical to your business success. That is where we come in. We make your designs come to life.

With years of expertise in thermoforming fabrics and mechanical engineering, nothing can stand in the way of your creativity.

We create the tools you need to design your garment to your exact specifications.

A Variety of Mold Forms to choose from

As a springboard for your project, you will have our entire product catalogue at your disposal.

Our technology will support your creative vision

Can’t find what you’re looking for? We will develop new mold forms for that perfect fit.

Sustainability

Sustainability, transparency, and fair working conditions have been part of our company culture from our very

beginning.

We ensure that working conditions are fair, pleasant and comfortable for our employees. As part of producing as little waste as possible, we reduce, reuse, and recycle whenever possible.

✿ Our electricity is 100% hydroelectrically generated and provided by Voralberger Kraftweken and from the solar panels on our roof.

✿ We are continually improving the storage system in our warehouse and minimising packaging.

✿ Our fabric scraps are reused, finding new life as filling for exercise equipment or as part of sewing or art projects. Please don't hesistate to contact us, if interested.

✿ Our packaging is environmentally friendly.

✿ The air purification system in our production hall removes pollutants in the air, safeguarding both our employees and the environment.

✿ We provide a cycle to work scheme for our employees.

Competence and Quality

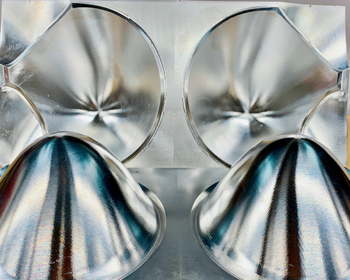

Since being founded in 2004, we have been experts in thermoforming fabrics, specialising in the development

and production of seamless bra cups. The cups are molded into various, seamless shapes.

The thermoforming is done by shaping the fabric with two heated metal breast shapes, for the fabric to take the shape of

the breast without having any seams.

For each cup size, there are mirrored mold forms for the left and for the right breast.

We can mould bra cups from size AA and can go all the way up to a K cup size.

We also cater to other sectors, even in different industries. From fabric manufacturing to tailoring to mesh filters for industrial machines.

Tailored Solutions For Individual Forms

✦ Forms adapted for special applications

✦ Adaptations of forms to existing foam cups

✦ Reproduction and production acquisition for existing products

✦ Development of new mould forms.

PRODUCTION

Our expertise is the formation and shaping of knitted fabric into seamless bra cups.

- Our Technology

- Bra Cup Molding Machines

- Cutting Tools

- CNC Milling Machine

- Mould Forms / Mold Shapes

Moulding machines

Produced with the most modern machinery.

Our bra cup molding machines and tools are

developed and made on site with adaptability and variability in mind.

Foam and Spacer

The production of foam and spacer bra cups requires expertise and specially developed moulds. After collaborating with our clients on the development of the moulds, we manufacture the cups to the highest standards.

3D Bra Cup Cutting Tools

Our mold forms fit your designs!

After the thermoforming process, the moulded 3D bra cups are cut

into the unique, customer defined shape. Each cutting template is completely unique to the client.

A Wide Variety of Mold Forms

When finding the base for their bra development, we offer our clients a large selection of mold shapes

and sizes to choose from, with cup sizes starting from AA and going all the way up to a K cup.

Hydraulic Bra Cup Die Cutting Machine

Fabric die cutting is fast, efficient, and accurate with our hydraulic presses.

The die stamping tools are tailor made to customer requirements.

In cooperation with each customer, our specialists in development and construction

are able to create unique solutions that meet the customers' expectations.

We make precise production ready cutting tools from your pattern prototypes.

CNC Milling Centre 5-Axis

With a CNC machine on-site, we develop the mould forms for your seamless bra cups on site. Our wealth of experience, enthusiasm, and a fantastic track record, offers you flexible, bespoke solutions.

BESPOKE PRODUCT DEVELOPMENT

TO YOUR SPECIFICATIONS

Our clients benefit from our many years of experience in implementing bespoke lingerie designs

Product Development

- Digital implementation of your templates

- Fast turnaround of sample orders

- Development of bra cup stamping tools

- Production of 3D bra cup cutting tools

- Creating precise production ready cutting tools from your bra cup patterns.

A large catalogue of our mould forms is at your fingertips, ready to aid you the development of your bra project.

The center gore/bridge size is also customisable, we adapt our mold forms to your products!

Supporting you in every step of your bra development journey

-

Do you have a project in mind?

We are more than a reliable manufacturer of molded bra cups.

We are a full-service provider, there to support the whole journey from idea realization to product implementation.

When working with us, you benefit from our many years of experience in bringing product ideas to life,

your inspiration inspires us.

Nothing can stand in the way of your creativity.

CLIENT TESTIMONIALS

.

“Unsere Geschäftsbeziehung mit HD besteht nun schon über 12 Jahre. Unser Unternehmen hinter Ulla Lingerie Féminine hat sich spezialisiert

auf die Herstellung von

hochwertigen Dessous in großen Cups.

Die Entwicklung der entsprechenden Moldformen ist eine große Herausforderung. Das erfordert eine enge und innovative Zusammenarbeit und die ein

oder andere Problemlösung.

Das funktioniert nur mit einem tollen Partner wie HD an der Seite.

DANKE! Wir freuen uns auf viele weitere gemeinsame Ideen und Projekte in der Zukunft.

Ulla Lingerie Féminine

www.ulla.de

Wir von THUASNE schätzen seit vielen Jahren die gute Zusammenarbeit und den engen Kontakt mit dem Team von HD.

Der Geschäftsführer, Herr Walter Donaubauer, hat stets ein offenes Ohr für unsere Bedürfnisse und eine schnelle sowie unkomplizierte Lösung parat.

Dank der gleichbleibend hohen Qualität der BH-Cups, die von HD für uns gemoldet werden, können wir unsere brustoperierten Kundinnen mit

exzellenten Produkten unterstützen

und ihnen damit einen sicheren und selbstbewussten Auftritt im Alltag ermöglichen.

Thuasne

www.thuasne.de

Offering high quality Products, very good cooperation, very good communication.

Miss Mary of Sweden

www.missmary.com

Wir arbeiten seit vielen Jahren mit HD Verformungstechnik zusammen und haben gemeinsam sehr anspruchsvolle Projekte erfolgreich bewältigt.

Umfangreiches technologisches Know How, kreative technische Lösungen und sehr freundliche und aufmerksame Mitarbeiterinnen und Mitarbeiter: Willkommen im "Home of Molding"!

Dresdner Spitzen

www.dresdnerspitzen.de

JOIN OUR TEAM

JOIN OUR TEAM

HD Limitless is a family business nestled in the picturesque Allgäu region of Southern Germany.

We are a small company with a big impact, being a leading supplier in the production of high-quality molded bra cups in Europe.

Join us in our mission, supporting women’s wellbeing by creating bras with the perfect fit!

We believe that the right bra not only supports the breasts, but also the femininity and self-confidence of the wearer.

Every day we ensure the satisfaction and well-being of thousands of women by processing a wide variety of textiles,

which later become beautiful bras.

We are looking for new colleagues to expand our dedicated team!

- Committing to the smooth running of the production process within your team

- Operation of production machinery and quality control of the product

- Working effectively and contributing to the improvement of your team's performance daily

- You enjoy working with textiles

- You are interested in experiencing the exciting world of the bra industry up close

- You have good manual dexterity

- It is important to you that your work is part of something bigger

- Precision and concentration, as well as reliability and punctuality come naturally to you

- You are willing to work in two shifts

PRODUCTION WORKER

Your Responsibilities:

Your Profile:

Does this feel like your perfect fit? Then get in touch by phone or email, we are looking forward to your application!

YOUR BENEFITS AT HD

- Long term and secure workplace

- Extensive training by our dedicated team

- Family working culture

- Winter Holiday Shutdown

- Bike to Work scheme

- Free fresh fruit available for all workersg

- Social club

- Late shift compensation

Does this feel like your perfect fit? Then get in touch by phone or email, we are looking forward to your application!

Do you have any other skills or experience that we should know about? Let us know!

We look forward to your application!

Contact HD

If you want to find out more about us, or want to work with us, contact us by phone or by email.

DEPARTMENTS

- Baumeister-Bufler-Straße 8

- +49 (0) 8387 / 92429-0

- info @ hdvt.de

- +49 (0) 8387 / 92429-0

- p.kasa @ hdvt.de

- +49 (0) 8387 / 92429-14

- m.nadashvili @ hdvt.de

Administration

Job Enquiries

Product Development / Production

Copyright HDVT

Impressum

HD Verformungstechnik

Walter Donaubauer

Baumeister-Bufler-Straße 8

D-88171 Weiler Simmerberg

Inhaber

Walter Donaubauer

Fon: +49 (0) 8387 / 92429-0

e-Mail: info@hdvt.de

Umsatzsteuer-ID: DE812050781

Verantwortlich für die Seite ist die Fa.HD Verfomungstechnik.

Vervielfältigung, Kopieren oder Nutzung der Inhalte und Bilder auf dieser Seite,

auch auszugsweise, ist untersagt.

Datenschutzerklärung

Die Betreiber dieser Seiten nehmen den Schutz Ihrer persönlichen Daten sehr ernst. Wir behandeln Ihre personenbezogenen Daten vertraulich und entsprechend der

gesetzlichen Datenschutzvorschriften sowie dieser Datenschutzerklärung.

Die Nutzung unserer Website ist in der Regel ohne Angabe personenbezogener Daten möglich. Soweit auf unseren Seiten personenbezogene Daten

(beispielsweise Name, Anschrift oder E-Mail-Adressen) erhoben werden, erfolgt dies, soweit möglich, stets auf freiwilliger Basis.

Diese Daten werden ohne Ihre ausdrückliche Zustimmung nicht an Dritte weitergegeben.

Wir weisen darauf hin, dass die Datenübertragung im Internet (z.B. bei der Kommunikation per E-Mail) Sicherheitslücken aufweisen kann. Ein

lückenloser Schutz der Daten vor dem Zugriff durch Dritte ist nicht möglich.

Server-Log- Files

Der Provider der Seiten erhebt und speichert automatisch Informationen in so genannten Server-Log Files, die Ihr Browser automatisch an uns übermittelt. Dies sind:

• Browsertyp und Browserversion

• verwendetes Betriebssystem

• Referrer URL

• Hostname des zugreifenden Rechners

• Uhrzeit der Serveranfrage

Diese Daten sind nicht bestimmten Personen zuordenbar.

Eine Zusammenführung dieser Daten mit anderen Datenquellen wird nicht vorgenommen.

Wir behalten uns vor, diese Daten nachträglich zu prüfen, wenn uns konkrete Anhaltspunkte für eine rechtswidrige Nutzung bekannt werden.

Google Maps

Diese Webseite verwendet das Produkt Google Maps von Google Inc. Durch Nutzung dieser Webseite erklären Sie sich mit der Erfassung, Bearbeitung sowie Nutzung der automatisiert erhobenen Daten durch Google Inc, deren Vertreter sowie Dritter einverstanden.

Die Nutzungsbedingungen von Google Maps finden sie unter "Nutzungsbedingungen von Google Maps".

Widerspruch Werbe-Mails

Der Nutzung von im Rahmen der Impressumspflicht veröffentlichten Kontaktdaten zur Übersendung von nicht ausdrücklich angeforderter Werbung und Informationsmaterialien wird hiermit widersprochen. Die Betreiber der Seiten behalten sich ausdrücklich rechtliche Schritte im Falle der unverlangten Zusendung von Werbeinformationen, etwa durch Spam-E-Mails, vor.

Quelle: e-recht24.de